DENTON (UNT), Texas — A nearly $350,000 grant awarded to a University of North Texas researcher by the Walmart Foundation and the U.S. Conference of Mayors is helping to bring manufacturing jobs back to the U.S.

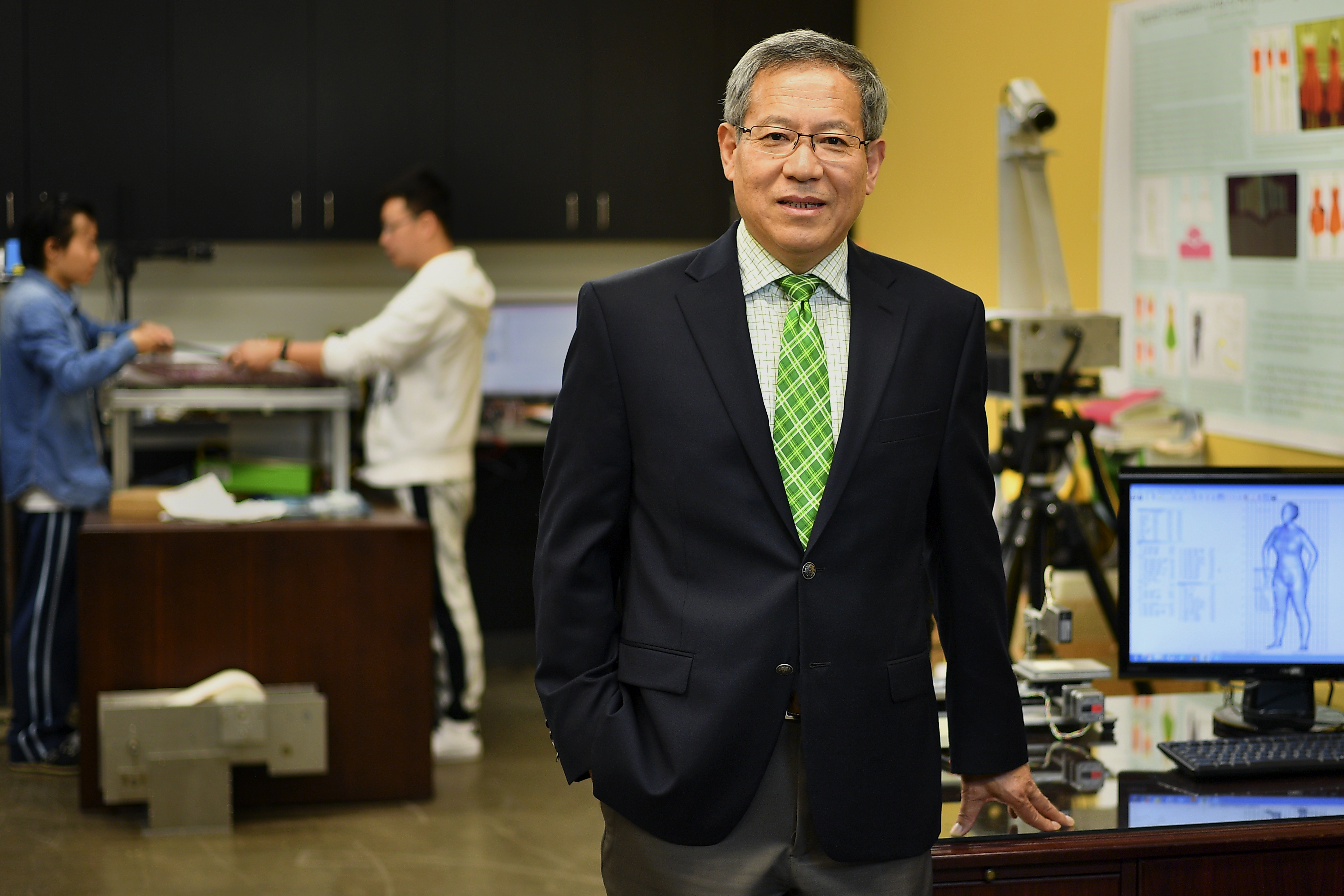

Bugao Xu, a professor and chair of the Department of Merchandising and Digital Retailing, received one of five grants in 2016 from the U.S. Manufacturing Innovation Fund to develop digital technology to detect flaws in fabric at domestic textile mills – saving companies time and money.

“U.S. competitiveness in the textile industry lags behind other nations because of high labor costs,” said Xu. “This is a solution that could save manufacturing companies big money, improve the quality of fabrics, reduce labor costs and boost textile production in the U.S.”

Defects are a big problem and can reduce fabric price by 45 to 65 percent, said Xu. Most fabric defects are preventable and correctable if discovered on the loom on time.

“Detecting weave defects is an integral part of modern weaving. While some devices are able to spot flaws, many are extremely difficult to be used on loom,” said Xu, adding that most fabric inspection systems are designed for post-weaving detections and don’t capture problems in real time.

Instead of relying on machines, human workers are still needed for quality assurance checks during and after the weaving process.

Xu aims to fix this costly problem by creating an on-loom fabric defect inspection system that uses contact image sensors to detect flaws, automatically stop the loom and alert workers to fix the cause of defects. Currently, his team is working on a prototype with the capability to rapidly capture high-resolution images as fabric passes beneath the machine and then use machine-learning algorithms to locate fabric flaws in those images.

The key is, however, to make the system affordable so that it can be used on individual weaving machines. A single textile mill can own several hundred modern looms, which results in a heavy capital cost, said Xu.

“It has to be a practical solution,” he continued. “There are already commercial systems in the world that do something similar, but those are very complex, expensive machines, and almost price-inhibitive to many textile manufacturers.”

The grant, which Xu was awarded while working at the University of Texas, was among a total of $2.84 million in grants that were given to five research and academic institutions in 2016. A total of $10 million in grants will be awarded during the next five years.

“Through these grants, we hope to help remove the barriers to revitalizing and growing U.S. apparel manufacturing, while creating more sustainable production processes,” said Kathleen McLaughlin, president of the Walmart Foundation and chief sustainability officer for Walmart. “The U.S. Manufacturing Innovation Fund is part of Walmart and the Walmart Foundation’s broader commitment to foster new economic growth and opportunity and create stronger communities.”